The Italian eyewear design company RES/REI is located near the historic town of Treviso in the Veneto (Italy). Invited to visit their HQ, studios and production department with a small group of Danish and Swedish opticians, we had the opportunity to learn about their unique style of making their frames. The company has a close relationship with Mazzucchelli 1849, with whom they create artistic custom colours and patterns that contribute to the signature looks of RES/REI eyewear.

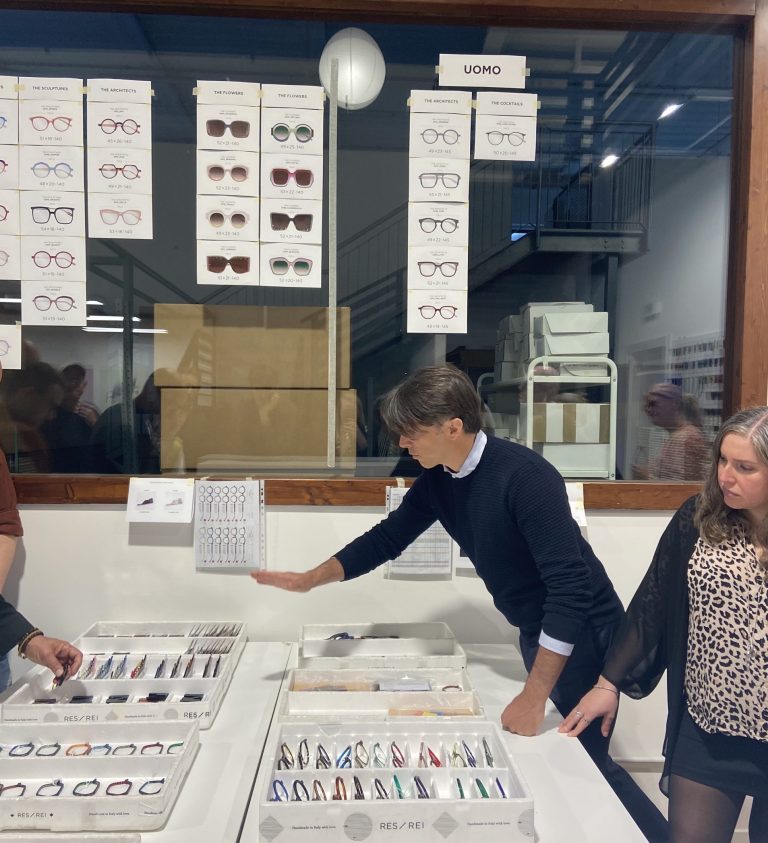

Situated in the green countryside outside Treviso, Veneto (prosecco country), RES/REI is a unique eyewear producer, balancing with artistry the traditions and passions of making Italian eyewear, with a contemporary, youthful mindset and innovative talent for design. Founder Oliviero Zanon, and a small team do close to every stage of the creative process and production at the location in the Veneto, with a few specialised steps outsourced to very local Veneto specialists. Particularly revered by opticians for their colours, the custom acetate hues and sophisticated patterns developed with Mazzucchelli 1849 create eye-catching design pieces with playfully stylistic combinations and finishes. Above: Oliviero Zanon shows Danish and Swedish independent opticians their colour archive and particular steps for developing colours and mixes of colours in the RES/REI collection (May 2023).

Requiring multiple steps for the design and production of the eyewear, the creative process begins in the HQ in Treviso, where Oliviero and team sketch designs and ideas for details and materials for each individual frame in a collection. The company is proud to have created its own carefully preserved archive of acetate samples of different patterns and colours used through the years, which now acts as a reference point and powerful inspiration for everything new they create. Prototypes of every single frame are also created in-house, ensuring that the colour combinations, gradients and patterns replicate the artistic nuances and intensity of colour required.

During the visit to HQ in May, the group toured the production rooms at RES/REI, developed over years to provide the perfect combination of manufacturing processes and hand-finishing. High-tech machinery is used for section cutting, section bonding (for example, for combining or “bonding” different colours) and nose piece bonding. Other steps in the first phase of production include the precision cutting of the fronts, and the tumbling of fronts and temples, a traditional technique used to smooth and enhance the surfaces of individual parts.

Production continues with many other precise phases including the fitting of the various parts of the frame, the bending stage to achieve the perfect curvature of the design and the hand polishing and finishing stages – all requiring human interaction, artisan expertise and know-how to achieve the finest possible results.

Model Copper in the Spring/Summer 2023 collection illustrates the complexity of the colours combinations and the refinement of a gradient effect. The metal temple core is enriched with a finely detailed engraving that is visible to the eye from within the clear acetate.

Through their particular ways of laminating the colours, working the acetate details and playing with the possibilities of colour, translucency and surface finishing all at once, RES/REI achieves a one-of-a-kind product style, firmly rooted in Italian spectacle-making tradition but all the while innovating with a modern point of view to reflect the avantgarde. To view the full collection at RES/REI, visit www.resrei.com

Eyestylist was invited to attend the event at RES/REI in early May 2023 with a group of visiting opticians from Sweden and Denmark. We also took a memorable trip by invitation to RES/REI’s acetate supplier, the world-renowned Mazzuchelli 1849 (www.mazzucchelli1849.it). We stayed at the hotel B&B Hotel Treviso in the centre of the historic city of Treviso. Eyestylist wishes to thank both RES/REI and Mazzucchelli 1849 for their kind hospitality.